Transform Your Procedures: Locate the Ideal Dirt Screen for Sale to Fit Your Requirements

Transform Your Procedures: Locate the Ideal Dirt Screen for Sale to Fit Your Requirements

Blog Article

Enhance Reusing Performance With Advanced Dust Screens for Arranging and Separation

In today's fast-paced and environmentally conscious globe, maximizing reusing efficiency has become a top priority for areas and sectors alike. And one vital solution that has acquired grip is the use of innovative dirt displays for arranging and separation. These cutting-edge displays provide an array of advantages, from enhancing recycling prices to decreasing waste contamination. However exactly how precisely do these displays function? What are the vital features to search for when considering their execution? And maybe most intriguingly, what are some real-life success stories showcasing the transformative power of sophisticated dirt screens? Join us as we check out these questions and more, revealing the very best techniques for applying these screens and reinventing reusing methods.

Advantages of Advanced Dirt Screens

Advanced dirt displays provide various advantages in boosting recycling efficiency. These cutting-edge screens are designed to properly arrange and separate products, guaranteeing that just clean and recyclable items are refined even more. Among the crucial advantages of advanced dust screens is their capacity to remove impurities and pollutants from the reusing stream. By effectively removing dirt, debris, and other undesirable materials, these screens help to keep the stability of the recycled materials, improving their worth and bankability.

In addition, advanced dust screens add to ecological sustainability by improving the total high quality of recycled products. By making sure that only tidy and unpolluted items proceed to subsequent processing phases, these screens aid to create higher-grade recycled items with enhanced market need. This not just promotes the round economy but additionally decreases the dependence on virgin products, preserving all-natural resources and decreasing carbon emissions.

Exactly How Advanced Dust Screens Work

To comprehend just how dust screens work, it is essential to grasp the essential concepts behind their operation. Advanced dirt displays are developed to successfully different dirt and particles from recyclable products, thus maximizing the recycling process. These displays use a combination of gravitational and mechanical pressures to achieve this task.

The operation of innovative dirt displays begins with the feeding of combined recyclable products onto the display surface. As the materials relocate along the screen, they encounter various sized apertures or openings. These apertures enable smaller sized bits and dust to travel through while maintaining bigger recyclable products.

The screen surface is commonly inclined at an angle, allowing gravity to help in the splitting up procedure. As the products relocate down the screen, the larger and much heavier recyclables continue to take a trip, while the lighter dirt and particles are carried away by gravity and fail the apertures.

Furthermore, progressed dirt displays are outfitted with vibration devices that aid to assist in the separation procedure. These resonances aid to loosen up and remove dust fragments, making sure that they can conveniently travel through the apertures.

Secret Attributes to Search For in Dust Screens

When selecting dust displays, it is necessary to take into consideration vital attributes that enhance performance and efficiency in the recycling process. These attributes play a crucial duty in optimizing the testing and separation of products, making sure a better result and lowering downtime.

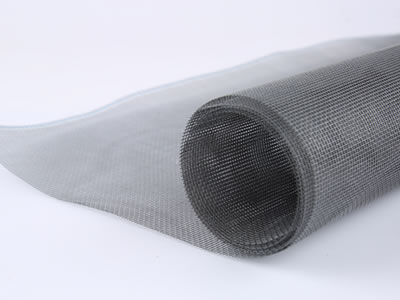

One key function to look for in a dust display is the size and form of the screening openings or mesh. The right hole size is necessary for effectively separating dust and other unwanted products from recyclable materials.

One more important feature to consider is the material and construction of the dirt screen. Screens made from high-quality and resilient materials such as stainless-steel or polyurethane are more resistant to damage, resulting in a much longer life expectancy and reduced upkeep costs. The building and construction of the display, including its reinforcement and support framework, should likewise be strong enough to stand up to the demands of the recycling process.

In addition, the style and design of the dust screen need to help with simple gain access to for upkeep and cleaning - dirt screen for sale. Displays with quick-change mechanisms or conveniently replaceable panels can reduce downtime throughout maintenance

Case Researches: Success Stories With Dust Screens

Numerous case research Visit Website studies have actually demonstrated the success and performance of using dust screens in the recycling market. These researches have showcased just how dirt displays can dramatically improve reusing effectiveness by getting rid of pollutants and increasing the pureness of recycled materials. One study conducted by a recycling center in the United States discovered that including dirt displays right into their sorting process led to a 25% boost in the recovery rate of recyclables. By effectively dividing dirt, rocks, and other particles from the recyclable products, the facility had the ability to produce cleaner and higher-quality recyclables, which More Help inevitably resulted in raised market need and improved earnings.

Another situation research study, performed by a recycling plant in Europe, concentrated on the advantages of making use of sophisticated dust screens in the separation of glass from various other recyclable products (dirt screen for sale). By executing dirt displays with adjustable setups, the plant accomplished an extra specific separation process, bring about a significant reduction in glass contamination within other recyclables. Consequently, the plant experienced enhanced arranging effectiveness, minimized waste, and increased overall recycling prices

These study highlight the positive effect that dirt displays can have on recycling procedures. By properly getting rid of dust and various other impurities, these screens contribute to higher-quality recyclables, raised healing rates, and improved success for recycling facilities.

Implementing Advanced Dirt Screens: Best Practices

The successful application of advanced dust displays calls for careful consideration of finest practices and market requirements. To optimize reusing efficiency, it is vital to comply with a set of guidelines when implementing these displays.

Second of all, it is essential to guarantee that the dirt displays are properly sized and mounted within the recycling system. This involves taking into consideration factors such as the flow rate of waste materials, the size of fragments to be screened, and the offered space within the facility. Correct installation will certainly make best use of the efficiency of the screens in removing dust and pollutants.

In addition, regular maintenance and cleansing of the dust screens are important to make sure ideal efficiency. This consists of regular examinations, elimination of any kind of accumulated debris or clogs, and replacing damaged components as required. By adhering to an upkeep timetable, the screens can remain to operate efficiently and effectively.

Last but not least, it is a good idea to remain educated regarding sector standards and improvements in dirt display modern technology. This expertise can assist reusing facilities stay ahead of the contour and make educated decisions when applying sophisticated dust screens.

Conclusion

To conclude, making use of innovative dust displays can greatly maximize recycling effectiveness by improving sorting and separation procedures. These screens provide numerous benefits and job by effectively getting rid of dirt and debris from recyclable products. Key functions to take into consideration when choosing dirt displays include toughness, ease of upkeep, and high sorting precision. Several success tales highlight the effectiveness of carrying out dirt displays in recycling centers. By complying with finest practices, organizations can enhance their recycling procedures and contribute to an extra sustainable future.

Advanced dust displays supply countless benefits in boosting reusing effectiveness. Advanced dirt displays are developed to effectively separate dust and debris from recyclable materials, therefore maximizing the reusing procedure.The procedure of sophisticated dirt screens starts with the feeding of mixed recyclable materials onto the display surface. These researches have showcased how dust screens can significantly improve recycling performance by eliminating contaminants and enhancing the pureness of recycled materials.In conclusion, the use of advanced dirt displays can substantially enhance reusing effectiveness by enhancing sorting and separation processes.

Report this page